Surface preparation

REMOVAL OF GATING SYSTEM AND GRINDING

The first rough processing procedure in the case of casting is removal of gating system and risers. A particular attention should be paid in order not to damage the processed piece. Thanks to specially adapted saws and properly selected tools we achieve optimal quality of this process.

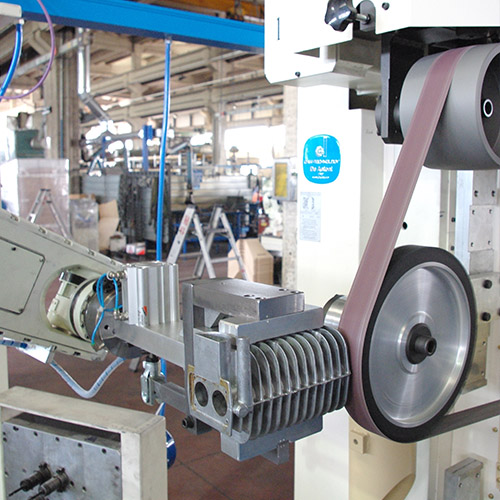

Grinding of aluminium castings is a difficult and demanding process. Depending on client’s expectations and requirements we grind castings manually and using automatic grinding machines in specially adapted grinding shop. Long experience allows us to select proper tools and experience of our workers guarantees quality and efficiency of the process.

AUTOMATIC GRINDING OF CASTINGS

In the case of serial production we offer the possibility to grind or, in some cases, polish castings on a specially prepared, robotic grinding and polishing station. This technology is dedicated mainly to performance of the final, ready-made product.

COATS AND ELECTROPLATED COATINGS

At the client’s request various coats can be applied to the ground castings or finished products. We have long experience in electroplated coatings – copper plating, chromium plating, nickel plating – also in cold-sprayed coatings – coloured chromium, metallic paint, and many other.